Product Solutions for Food and Beverages Industry

The food and beverage industry are companies involved in the processing of raw food materials, packaging, and distribution. This includes fresh, processed foods as well as packaged foods, alcoholic and non-alcoholic beverages. Products meant for human consumption, aside from pharmaceuticals, comes from this industry.

Food and beverage industry requires high standards for safety and reliability that requires the high quality instrumentation requirements for this industry.

Our company is built to deliver high quality and innovative products, and providing the best value for investment and provide new and effective solutions to increase competitiveness, efficiency, and profitability for total customer satisfaction

Applicable Products

Great Plains Industries

A. Oval Gear Meter

The Micropulse and multipulse Oval series PD flowmeters provide precise volumetric flow measurement of clean liquids found in a broad range of industries including automotive, aviation, mining, power, chemical, pharmaceutical, food, paint & petroleum. Applications include the distribution of fuels, fuel oils, lubricants, alcohols, solvents, blending of bio & ethanol fuels, metering of chemicals, grease, adhesives, ink, insecticides & non-conductive liquids either pumped or gravity fed.

- Small capacity Flowmeters

Small capacity flowmeters provide precise volumetric measurement of small quantities of liquids or low flows found in a broad range of industries including automotive, aviation, mining, power, chemical, pharmaceutical, food, paint, petroleum & environmental. Applications include the metering of additives for fuel, consumer products, water treatment & flotation cells, corrosion inhibitors, catalysts, emulsifiers, oils, grease, fragrances, adhesives, solvents, ink & insecticides.

Features / Benefits

- High accuracy & repeatability, direct reading flowmeter

- No requirement for flow conditioning ( straight pipe runs )

- Stainless Steel rotors (Optional PPS Rotor for OM008 meter)

- Measures high & low viscosity liquids

- Quadrature pulse output option & bi-directional flow

- Integral 4-20mA output option

- Optional Exd I/IIB approval (ATEX, IECEx)

- PF option available for metering pulsating flows

General specification

- Flow rates: 0.5 ~ 550 litres / hr. (0.16~ 145 USgal/hr.) *

- Sizes: 4~8mm (1/8”~3/8” NB)

- Materials: Aluminum, 316 Stainless steel

b. Medium capacity Flowmeters

Medium capacity flowmeters provide precise volumetric flow measurement of clean liquids found in a broad range of industries including automotive, aviation, mining, power, chemical, pharmaceutical, food, paint & petroleum. Applications include the distribution of fuels, fuel oils, lubricants, alcohols, solvents, blending of bio & ethanol fuels, metering of chemicals, grease, adhesives, ink, insecticides & non-conductive liquids either pumped or gravity fed.

Features / Benefits

- High accuracy & repeatability, direct reading flowmeter

- No requirement for flow conditioning ( straight pipe runs )

- Stainless Steel rotors (Optional PPS Rotor for OM008 meter)

- Measures high & low viscosity liquids

- Quadrature pulse output option & bi-directional flow

- Integral 4-20mA output option

- Optional Exd I/IIB approval (ATEX, IECEx)

- PF option available for metering pulsating flows

General specification

- Flow rates: 1 ~ 580 litres / min. (0.26~ 150 USgal/min. )

- Sizes: 15~50mm (1/2”~2” NB )

- Materials: Aluminum, 316 Stainless steel or Ryton (PPS)

Note:

NMI Approved Meters

Many applications require the use of NMI approved meters. Flomec Series Flowmeters 1” and above are available with optional NMI pattern approval with quadrature pulse output.

B. G Series Turbine Meter

General Specifications:

- Accuracy: +/- 0.5% of reading

- Flow Range: 0.6 to 600 GPM (3.0 to 2,271 L/min)

- Temperature: -450 to 300 deg F [-268 to 426 deg C]

- Pressure: 2,500 to 5,000 PSI (170 to 340 Bar)

- Meter Sizes: 1/2″ to 3” (15 to 80 mm)

- Meter Body Materials: Stainless Steel

- Fitting Connections: NPT, BSP, Sanitary and ANSI Flange

C. G2 Series Turbine Meter

General Specifications:

- Accuracy: +/- 1.5% to 0.75% of reading (Depending on Pipe Size)

- Flow Range: 1.0 to 200 GPM (3.8 to 760 L/min)

- Temperature: -40 to 250 deg F w/ display (-40 to 1210 deg C w/ display)

- Pressure: 1,500 to 3,000 PSI (102 to 207 Bar)

- Meter Sizes: 1/2″ to 2” (150 to 50 mm)

- Meter Body Materials: Aluminum, Stainless Steel and PVDF

- Fitting Connections: NPT, BSP Thread, Sanitary Flange and True Union

D. QStar Ultrasonic Meter

General Specifications:

- Accuracy: Up to +/-1% of reading

- Flow Velocity Range: +/- 98.42 t/sec (30 m/s)

- Operating Temperature: -4 to 140 deg F (-20 to 60 deg C)

- Transducer Temperature: -40 to 300 deg F (-40 to 150 deg C)

- Pipe Sizes: 1/2” to 240” (10 to 6000 mm)

KATRONIC

Katronic Technologies Ltd. specialise in clamp-on ultrasonic flow meters and non-invasive process measurement instrumentation. The KATflow clamp-on flow meters work on the transit time ultrasonic principle. This, put simply, involves sending and receiving ultrasonic pulses from a pair of sensors and examining the time difference in the signal. This is a more direct method of determining flow rates than some other systems and provides reliable measurements.

Whether they are portable instruments or designed for permanent installation, the Katronic KATflow ultrasonic clamp-on flowmeters are cost effective devices for beverage to save resources, energy, and as a result costs. For these reasons and due to Katronic’s excellent and flexible customer service, leading companies of the brewing industry have decided to use KATflow Flowmeters.

General Advantages of Katronic Ultrasonic Clamp-On Flowmeters

1. No Shut Down:

By mounting the flowmeter on the outside of the pipe, there is no requirement to shut the flowing system down. This means no lost production.

2. No Engineering:

As the sensors are mounted externally to the pipeline, there is no need to conduct costly pipe modification, no need for specially trained manpower and no risk of any kind of leakage.

3. No Hidden Costs:

The only expense with a clamp-on unit is the purchase cost. Engineering work, down-time and trained staff are all expensive additions to more conventional metering solutions. Furthermore, on non-ultrasonic meters the hidden material costs of bolts, seals, washers etc. can more than double the price of an instrument.

4. Maintenance Free:

Katronic ultrasonic clamp-on flowmeters do not contain moving parts, which could wear out. Moreover, the sensor casings are manufactured of stainless steel and are not in contact with the flowing medium, which helps avoid corrosion. As a result, maintenance is not necessary.

5. High Accuracy:

For volume flow measurements, the KATflow flowmeters achieve an uncertainty of down to only 1.0% of the measured value depending on the conditions of the specific flow application. A decreased uncertainty of approx. 0.5% can be achieved by carrying out an on-site process calibration. In case of flow velocity measurements, the KATflow flowmeters achieve an uncertainty within 0.5% of the measured value.

6. User-Friendliness:

As the ultrasonic flow sensors are simply clamped onto the pipe surface, KATflow flowmeters can be installed without the need to open pipes. The sensors are fixed to the pipe using special metal chains, straps or mounting rails. Every instrument of the KATflow series is equipped with a set-up wizard and the Audible Sensor Positioning AssistantTM, which guide the user step-by-step through the installation process. As a result, it only takes a few minutes to install and set up the flowmeter.

Advantages Regarding Process Conditions and Hygenic Standards

1. Hygiene:

Installing a clamp-on flowmeters does not create intrusions which allow bacterial growth inside the pipe. This means that there is no risk of contaminating the product.

2. Variability:

As the sensors are never in contact with the flowing medium, the portable flowmeters can be used on many different applications regardless of the type of fluid. In addition to that, the instruments work on all common pipe materials and diameters from 10 mm to 3,000 mm.

3. Low Response Time:

With a response time of only one second, the KATflow Flowmeters can measure rapidly changing flow velocities.

4. High Temperature Tolerance:

The KATflow ultrasonic flowmeter sensors are designed to withstand temperatures ranging from -30 °C to 130 °C and more. As a result, they can be used on any application involved in or related to the brewing process.

5. Measuring Temperature Changes and Energy Consumption:

Whether you want to determine the cooling rates during the wort cooling process, or if you want to measure temperature related energy consumption to fine tune heating or cooling systems for higher system efficiencies: The KATflow 230 and 150 flowmeters enable the brewer to monitor the temperature changes of almost any flowing liquid.

6. No Pressure Drop:

Externally mounted sensors mean that the Katronic Flowmeters have no effect on the flowing liquid and will not cause a pressure drop across the measurement location.

7. Ideal for Monitoring CIP Processes:

Due to their contactless ultrasonic flow measurement technique, low response time, and the high temperature tolerance of the flow sensors, Katronic flowmeters are ideal to monitor CIP flushes.

A. Fixed installed clamp-on ultrasonic flow meter

The KATflow 150 is for permanent flow metering applications. Its modularity offers comprehensive configuration options to make the instrument suitable for everything from simple water flow measurements to energy flow monitoring, automated process control and product recognition

Features:

- For pure, clean, dirty and aerated liquids

- Bi-directional flow measurement

- Heat quantity measurement function (optional)

- Dual-channel flow measurement (optional)

- Meter diagnostic functions

- Incorporated bi-directional totalizer

- Data download via RS 232 or USB cable

- Real time data transfer possible

- Intuitive flow meter menu and Setup Wizard

General Specifications:

- Pipe diameters: 10 mm to over 3,000 mm (3 m)

- Temperatures: -30 °C to +200 °C

- Accuracy: ±0.5 % (velocity)

- Process outputs incl. Modbus and HART* (optional)

- Internal data logger for 100,000 measurements

- Unique Audible Sensor Positioning Assistant

Density / concentration measurement option

- Ex approved version available

B. Hand-held clamp-on ultrasonic flow meter

The KATflow 200 is an innovative portable flow meter providing engineers with a robust, easy-to-use and lightweight instrument that offers the measurement performance of more complex and expensive devices.

Features:

- For pure, clean, dirty and aerated liquids

- Bi-directional flow measurement

- Heat quantity measurement function (optional)

- Dual-channel flow measurement (optional)

- Meter diagnostic functions

- Incorporated bi-directional totalizer

- Data download via RS 232 or USB cable

- Real time data transfer possible

- Intuitive flow meter menu and Setup Wizard

- Robust housing with rubber shock protector

General Specifications:

- Pipe diameters: 10 mm to over 3,000 mm (3 m)

- Temperatures: -30 °C to +200 °C

- Accuracy: ±0.5 % (velocity)

- Battery operation: Up to 24 hours

- Mains operation: Unlimited

- Internal data logger for 100,000 measurements

- Dedicated pipe wall thickness gauge (optional)

- Incorporated bi-directional totalizer

- Meter diagnostic functions

- Data download via RS 232 or USB cable

C. Portable clamp-on ultrasonic flow meter

The KATflow 230 is a portable clamp-on flow meter with two measurement channels offering a variety of optional features. It is a compact and robust instrument that comprises additional functions that can turn it into more than just a flow meter.

Features:

- For pure, clean, dirty and aerated liquids

- Bi-directional flow measurement

- Mains operation: Unlimited

- Heat quantity measurement function (optional)

- Dual-channel flow measurement (optional)

- Internal data logger for 100,000 measurements

- Dedicated pipe wall thickness gauge (optional)

- Meter diagnostic functions

- Incorporated bi-directional totalizer

- Data download via RS 232 or USB cable

- Real time data transfer possible

- Intuitive flow meter menu and Setup Wizard

- Robust housing with rubber shock protector

General Specifications:

- Pipe diameters: 10 mm to over 3,000 mm (3 m)

- Temperatures: -30 °C to +200 °C

- Accuracy: ±0.5 % (velocity)

- Battery operation: Up to 24 hours

- Process outputs (optional)

- Incorporated bi-directional totalizer

- Real time data transfer possible

- Intuitive flow meter menu and Setup Wizard

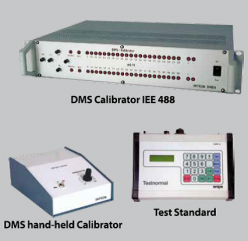

Flow Technology

Flow Technology worked with the winery to identify the optimal flow measurement solution for a check and balance system in compliance with TTB regulations. The EL 2400 Electromagnetic Flowmeter was chosen due to its sanitary design and measurement accuracy. It was paired with the MC 308 Display/Transmitter.

EL 2400 Electromagnetic Flowmeter

The EL 2400 provided the winery with a sanitary flowmeter that has no moving parts. This rugged mag meter is able to handle the solids content (e.g., grape skins, seeds, etc.) that may be in the wine in the early stages of production, and delivers the accuracy required for the TTB audit. The EL2400-025 is a one-inch meter, which was specified based on flow rate data provided by the customer. The MC 308C transmitter was selected for its display capability and 4-20 mA analog output.

System Description:

The EL 2400 Series flowmeter is specifically designed for sanitary applications. The housing is PTFE lined stainless steel. The standard electrode material is 316L SS with options for Hastelloy C and Titanium. Available in line sizes from 1–4 inches, the meter is capable of operating over a temperature range of -40 to 284 degrees F. The MC 308C transmitter is designed to display rate and total flows as well as provide multiple digital and analog outputs. It can be flowmeter mounted or remotely mounted with the supplied interconnection cable. The transmitter is also capable of reverse flow indication, alarms, extensive filtering, and diagnostics for empty pipe detection and electrode malfunction.

Technical Information:

- Flow Meter: EL2400-025ATCXPLCA

- Transmitter: MC308CCVM2D3C21N

- Flow Rate: 1.6–80 GPM

- Fluid: Wine

- Temperature: Ambient

GHM Messtechnik

A. Process Instrumentation

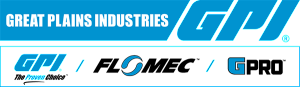

a. Process Connection

It is important to chose an adequate process connection for each application to get a hygienic solution conforming to standards.

Diameter, volume and design characterize dimension and type of connection; medium, temperature and pressure define the possible measuring methods. We offer hygienic and easy-to-clean standard and special process connections for all methods.

Advantages:

- Thread size M12, G, G1

- Leakage drilling

- Flexible modular adaption to all established process connections, i.e.:

Triclamp, SMS, Aseptic flange connection DIN 11864, Varivent, DRD flange,

DIN-/ISO-flange

Application:

- Mounting on piping, tanks, boiler and other receptacles

b. Temperature measurement (GTL)

The temperature probe series GTL of the GHM group provides more than 22 basic versions. This ensures best solutions for most diverse applications in pharma, food and beverage industries.

- Probes

- Process connection M 12, G . or compression fitting (without thread)

- Compact design

- Optionally with neck tube

- Electric connection M 12 plug or cable connection

- Several probe lengths and probe diameters

- Protection class IP67 or IP69K

- Process connection and protective tube made of stainless steel 1.4404

- Conversion rate ≤ 100 ms

- Fast respond to small changes

- 16-bit A-/D-converter

- High resolution and stability

- High accuracy

- Configuration according to customer preferences

- Programming adapter or software enable customer to carry out configuration

- Transmitter

- Clamp-on temperature probe GTL7.. Temperature monitoring without media contact

- Change / cleansing without process break down

- Insensitive to vibrations due to spring seat of sensor and firm fixing of adapter

- Optimized heat transfer due to 935 silver plate

- Fast response time and high accuracy due to integrated pipe wall correction

- Tube standards: DIN11850 series 2, DIN11866 series B, ISO 1127, ASME (DIN 11866 series C, OD-tube)

Advantages GTL:

- Temperature range -40..+200 °C

- Wide range of types

- Optional head transmitter

- Tapered measuring tips ensure short response time

- High accuracy (cl. A, cl. AA)

- Available with calibration certificate

- Variable installation length

- Protection class IP67 or IP69K

- Evaluation electronics (Ex-Schutz, Profibus, SIL 2)

Application

- Process monitoring and controlling

- CIP- or SIP- process control

c. LIMIT LEVEL

I. Capacitive limit level measurement (MLC)

Years of experience with continuously measuring level sensors helped us to develop a new measuring method for level switches which has already been filed as patent. Established systems use an oscillating circuit with the medium as capacitor. In contrast, the new method measures the charge carrier capacity of the medium. The conductivity of the medium does not influence the measuring value.

Advantages:

- Process connection G.

- Power supply 24 V DC

- PNP- or NPN- output

- Programmable via GHMware

II. Conductive limit level measurement (MLR)

This is a very cost-effective but also flexible method for limit level measurement. The probe can be designed as single or multi rod. The probe rods can be subsequently shortened and bent to fit them optimally to the measuring situation. The evaluation electronics can be installed in the sensor head or in a switch cabinet.

Advantages:

- Process connection M 12, G ., G 1

- Electrode length: 5..2000 mm

- Sensors with integrated electronics (optionally)

- Up to 5 electrodes, PFA coated (optionally)

- Conductivity range > 2 μS/cm

- Programmable via GHMware

Application:

- Multistage limit level detection of liquids in tanks or pipes

- Pump protection

B. Flow

The electronic flow monitoring with calorimetric measuring method does not need any moving parts in the flow (i.e. no turbine wheel or float). Therefore this sensor can be also used with aggressive media. Continuously measurements of smallest quantities of – for example – flavorings, liquors, water, etc. or chemically aggressive media is the main application field of the flow-meter HFK35-FIN.

a. Flow measurement of smallest quantities (HFK35-FIN)

Advantages HFK35-FIN:

- Several tube dimensions (6, 8 and 10 mm) adequate squeeze or screw terminals

- Flow: 0,001..10 l/min

- Pressure range: -1..+10 bar

- Accuracy: +/-2 %

- Application:Monitoring and measuring of smallestflows, Leakage control

b. Calorimetric flow measurement (HFK)

Advantages of further HFK-sensors:

- Process connection: TriClamp or G .

- Flow velocity water: 0,1..3 m/s

- Several evaluation electronics

- Application: Controlling and measuring

c. Electromagnetic flow measurement (MFI)

The voltage inductively produced by a conductive liquid in a magnetic coil depends on the flow velocity. This correlation is used for electromagnetic flow measurement. Advantages of this method are that no moving parts are necessary, that it causes only little pressure loss and that the same probe can be used

for a wide range of tube diameters.

Advantages:

- Variable process connection

- 14 diameters 3..100 mm

- Power supply 24 V DC

- Extremely compact

- Rotary head

- Completely made of stainless steel

Application:

- Flow measurement for all conductive liquids and pastes

- Process monitoring and control

- Continuous process dosing

- Filling of receptacles

- Batch-wise processes

- Minimum conductivity ≥ 5 μS/cm

C. Level

a. Hydrostatic level measurement (SA11 / TA1010)

The level measurement is done by measuring the hydrostatic pressure. Pressure is created by the liquid column above the sensor and is directly proportional to the fill level. The results can be visualized or processed by means of evaluation electronics adapted to the sensor.

- Level measurement for any tank shape via pressure measurement

- High accuracy ≤ 0,5 %

- Differential pressure measurement via double pressure measurement and evaluation electronics

- Complete stainless steel version

- Protection class IP65 or IP68

- Suitable for tank linearization via TA1010 or TA9648 evaluation electronics (6 Tank geometries as well as selectable special tank shape

b. Capacitive level measurement (UNICON-CL)

- Measuring ranges 0..200 mm to 0..3000 mm

- Units (mm, cm, in, ft, yd, m) programmable

- PTFE-measuring rod with G .-connection thread

- Compact design in 2-wire technology

- Outputs: 2 x 4..20 mA (for level and temperature), electrically isolated 2 x transistor switching outputs

- Protection class IP65

- Accuracy 0,5 % }2 mm

- Constant temperatures up to 120 °C

Application:

- Liquid, conductive adhering media

c. Potentiometric level measurement (MLP)

The MLP series continuously measures the level of all flowable media with a 3-pole rod probe. Using electrostatic induction effects allowed us to move the reference pole into the probe. Therefore an electric connection is not necessary any more at the tank. This enlarges the field of application; i.e. measurements in glass or plastic tanks.

- Dynamic measuring of fill levels for as little as 5 cm up to more than 2 m

- Minimum conductivity ≥ 5 μS/cm

- Measuring method independent of overpressure

- Only one measuring rod for metal or plastic tanks

- Applicable for permanent ambient temperatures up to 130 °C

- Several process connections

- Rod lengths with millimeter precision

d. Weighing measurement (DMS50 …)

- Transmitter without contact to medium

- Strain gauge input / Ex approval

- Measuring range from 0..2 kg to 0..5000 kg, maximum 0..100 t

- Basic accuracy 0,02 % to 0,1 %

- Repeat accuracy ≤ 0,03 %

- Max. overload 150 % to 200 %

- Protection class IP40 to IP67

e. Electrical transmitter (DMS50)

- 1 or 2 effective directions

- Teach-in function

- Tare function

- Simulator function

- Unit selectable (kg, t, N, kN, Nm, bar)

- Min- / max- value memory

- LED- or LCD- display

- Basic accuracy < 0,1 % to < 0,025 %

- Modbus- / Profibus DP- connection

- Up to 4 alarm outputs

Application:

- Level measurement in complete tanks

- Control of batch processes

D. Analysis Measurement

a. Capacitive DK-meter (MLC433 / 437)

The MLC43x is used for monitoring the dielectric constant DK of a product. For example oil, water mixtures can be monitored with this device. Freely scalable current output is integrated for value output. A LCD-display shows the current status and measuring value.

- DK-measuring range 1..175

- Accuracy ≤ 1 %

Application:

- Media separation via DK (CIP-control)

- Production quality control via DK

- Detection of powdery median (sugar, flour, coffee powder, spices, baking powder, …)

b. Conductive conductivity meter (UNICON-LF)

The measurement with conductive 2- and 4- pole sensors is the most widespread method in practice. The variety of process connections allows measurements in almost every application – ranging from water to aggressive acid.

- Measuring every conductivity ranges till ultra-pure water

- Production monitoring via DK

- 0..5 μS/cm to 0..500 mS/cm

- Temperature compensation

- Accuracy ≤ 0,5 %

c. pH- / ORP-measurement (UNICON-pH)

One of the most important values in process measurement becomes child’s play with our converters and display units. Working and connecting, configuration and even calibration is as intuitive as possible.

- Single-rod measuring cell

- Temperature compensation

- Measuring range for pH / ORP

- Accuracy ≤ 0,2 %

E. Laboratory Measurement

a. New handheld instruments

The housing design of GHMsilverline has been thoroughly adapted to its current and future applications.

The shaping is ergonomically optimized, prehensile areas and fields of view are clearly recognizable. Haptics, interface and product graphics support intuitive operation. Maximum variability for various physical values are achieved by only few components. Depending on equipment variant and measuring unit the basic housing can be optimally fitted to its specific use – therefore it is possible to focus

on cost efficiency or maximal comfort.

Special features:

- Robust and waterproof housing

- Waterproof connectors

- Compact dimensions

- Resistant silicone protective cover

- Easy handling

- Long battery life

- Many functions: min- / max value memory, auto-hold, data logger*,

analog output*, serial interface*, etc.

F. Industrial Electronics

a. Display / Controller

Visualization is the most important factor monitoring and displaying processes and application flows for the user. Our range of displays for front panel or direct mounting offers solutions for nearly all measurement quantities and physical units. A common feature of the displays is easy configuration via front panel buttons or DIP switches plus manifold options with relay and analog outputs. Use under harsh conditions is feasible due to environmental class IP65. If you have not found the appropriate display for your application yet, please do not hesitate to ask for a customer-specific solution.

Advantages:

- Dimensions 48 x 96 mm / 24 x 48 mm

- Universal Inputs

- Standard signal

- Resistance

- Frequency

- Speed

- Counter

- Difference

- Pressure

- Flow

- Cycle time

- Conductivity

- pH value

- Productivity

- Temperature

- Level

- Relay switching outputs

- Self diagnosis

- Programmable characteristic

- Transmitter power supply, isolated

- Serial Interface

- Min- / Max value memory

- EASYBus connection is possible

b. Data Logger / EASYBus

Advantages of Data Logger:

- Stand-alone application

- Large data memory (up to 250.000 data sets)

- Long battery life > 5 years

- Individual programming of recording interval and recording time

- Logger for temperature-, climate-, standard signal-, humidity-, impulse-, operating state measurement

Advantages of EASYBus:

- Minimum amount of installation and planning

- Display and monitoring system for several measurement points

- Unrivaled cost/performance ratio

- High flexibility: Subsequent modifications and extensions possible at any time

Application of EASYBus:

- Cooling chambers (temperature monitoring)

- Heating / air conditioning / ventilation (temperature, humidity, CO2-monitoring)

- Utility rooms / computer rooms / laboratories (temperature, humidity)

- Manufacturing rooms (temperature, relative humidity, CO2)

c.Switching and Monitoring Devices

Our switching and monitoring devices ensure the safe operation of an installation. The devices are freely configurable or programmable with a free choice of functionality.

- Threshold switch

- Isolation guard

- Power monitoring

- Emergency relay

- Safety temperature limiter

d. Transmitter

Signals from Pt100, thermocouples, strain gauges, or resistors cannot always be processed directly. Otherwise the signal follows a function needing processing as a linearized standard signal. For these and other signals and applications we offer transmitters. In most cases the transmitter can be enhanced with alarm contacts for a safe shutdown in case of emergency.

- Signal conditioning

- Linearization

- Characteristics transformation

e. Isolating Converters

Independent of the size of an installation, many failures and problems relate back to noisy signals or electrical potential mismatch. The solution is the galvanic isolation of the signal. With a universal design nearly all devices only isolate signals, but also convert signals.

- Galvanic isolation

- Power feed isolation

- Switching repeater isolation

- Transmitter isolation

f. Power Supply

DC power supplies and DC/DC-converter in standard housing for wall- or DIN rail mounting.

- Galvanic isolation input / output

- Adjustable output voltage

- Stabilized, short circuit protected

- Power limiting with positive characteristic

- Self-start after short circuit

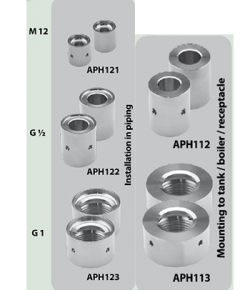

g. Calibration and Testing

Calibration devices for strain gauge amplifiers with manual or IEEE488 operation. Bridge resistances 120, 350, and 1000 Ohms. Sensitivities from 0,1 to 50 resp. 250 mV/V in 10 resp. 20 steps. Accuracy } 0,02 %. Test standard for physically correct simulation of strain gauge bridges, potentiometers, thermocouples, RTDs, current, voltage, and tachometer generators. The microprocessor used allows direct entry of sensor values as physical quantities. Calibration and nominal values are accounted for as well.

G. Peripheral Measurement

a. Level

Inspection glasses for vertical mounting in various lengths to monitor fluid levels and visual appearance. Float gauges for vertical mounting in various lengths and designs monitoring fill levels with one or more switch points. Float gauges for horizontal mounting monitoring fill levels with one contact or with capacitive measures. Ultrasonic method for granules and ductile materials avoiding direct contact.

b. Temperature

GHM Messtechnik offers an extensive range of measuring devices and probes for the measurement of temperature. Temperature probes are available in very different types with Pt100 / Pt1000 or thermocouple, as data logger, with integrated electronic (transmitter), ATEX-Protection or Display. There are also Bi-metal monitors for temperature control in strong design, external adjustable temperature switch and platinum temperature meter with high accuracy. All can be combined with transmitters FLEX-T (switch, analog, or frequency output) or OMNI-T (switch, analog, or frequency output and LED display).

- Injection probe

- Immersion probe

- Surface probe

- Air / gas probe

- Asphalt probe

- Clip-on probe

- Pipeline probe

- Radio-based probe

- Temperature

- Humidity

- Pressure

- Conductivity

- pH / ORP

- O2 / CO / CO2

- Flow

c. Pressure

- Membrane pressure monitor with settable switching point

- Pressure meter with thick-film sensor and protected pressure cell

- Stainless steel meter with flush mount membrane in 2-wire technology for combination with transmitters FLEX-P oder OMNI-P

- Ceramic pressure cell in stainless steel housing

- All pressure sensors are available also with wireless transmitter

d. Flow

- Piston valve design

- Piston in line design

- Float

- Paddle

- Dynamic flap

- Gear wheel

- Bolt

- Calorimetric

- Magnetic-Inductive

- Vortex

- Sight glass

- Flap

- Sphere

- Flow limiter

e. Filtration

Magnetic filter with microstrainer and magnet plug in solid construction, micro mesh 5..300 μm with

clear-sight lid.

Centec

Centec is a privately owned group of companies. With a focus on the processing industries, we are rapidly growing in the major world markets. We have a global sales and service structure, with our own subsidiaries and a network of qualified distributors. Our international operations include mechanical, electrical and process automation engineering, with skid manufacture and pipework fabrication; as well as our own switch cabinet production. This infrastructure allows efficient logistics, short lead times and strict adherence to delivery deadlines. The quality of our products is excellent, so is the price-performance ratio.

A. CARBOTEC

Application and Measurement Principle:

The content of carbon dioxide (CO2) has a strong influence on the quality and taste of beer, sparkling wine, soft drinks, mineral water and various other carbonated products. Therefore, breweries and other beverage and food companies continuously measure and control CO2 concentrations with highest precision throughout the entire manufacturing process.

CARBOTEC TR-PT: The carbonated liquid flows through a measurement chamber. By increasing the volume of the chamber, a gas phase is generated. The partial pressure difference of CO2 forces the CO2 out of the liquid into the gas. This changes the pressure inside the chamber. By pressure measurement, the CO2 content is calculated. CARBOTEC NIR: While transmitting a sapphire crystal, infrared light is reflected at the crystal surface which is in contact to the carbonated liquid. The CO2 molecules absorb the light and decrease the intensity. By intensity measurement, “true” CO2 content is determined. CARBOTEC NIR can be used to detect carbon dioxide even when CO2 is not the only gas in the liquid. Without any moving parts in the sensor head, the new generation of CO2 sensors is virtually maintenance free.

B. BEERMONITOR

Application and Measurement Principle:

Brewing is divided into milling, malting, mashing, lautering, boiling, fermenting, storage, filtering and filling. Fermentation begins after yeast is added to the cooled wort. During this stage fermentable sugars are metabolized mainly into alcohol and CO2. By combined measurement of density and sound velocity, both extract and alcohol can be determined. This is done after filtering, before filling and during optional blending. While the BEERMONITOR allows calculating the Original Gravity (OG), the PLATOMONITOR is used for OG determination only.

For density measurement, the liquid flows through a U-shaped tube. While the tube is electronically excited to oscillate at resonance, the oscillation frequency is observed. Any change in the fluid density has an impact on the detected signal and can thus be identified. At the same time, the speed of a sound pulse between a transmitter and a receiver is measured. The sound pulse is created by piezo-elements and moves perpendicular to the product flow. Based on the correlation between concentration and density resp. sound velocity, the concentration of the

3-component liquid is calculated.

C. CARBOTEC

Application and Measurement Principle:

The content of dissolved oxygen (DO) has a strong influence on the quality and taste of beer, beverages and various other food products. Excess O2 can result in a significantly reduced shelf life. Therefore, breweries and other beverage and food companies continuously measure and control O2 concentrations with highest precision throughout the entire manufacturing process. Typical applications in food and beverage industries include the determination of dissolved oxygen in deaerated water used for processing the final product.

An indicator layer on a small glass component (“optical window”) installed in the measuring head is illuminated with blue-green-light. When the indicator molecules absorb the incident light they are promoted to a higher energy state. After a certain time they convert back to their ground state during which a detectable red light is emitted. If O2 is present the energy is transferred from the indicator molecules to the oxygen. By detecting the red light, OXYTRANS determines the O2 content with highest precision.

D. RHOTEC

Application and Measurement Principle:

Brewing is divided into milling, malting, mashing, lautering, boiling, fermenting, storage, filtering and filling. Lautering is the separation of the extracts won during mashing from the spent grain to create wort. During boiling hops are added which contribute aroma and flavor compounds to the beer. Lautering and boiling take place in the brewhouse and are controlled depending on the amount of extract. Breweries need to measure the extract concentration with precision to maintain beer quality. For the measurement of this 2-component system consisting of water and extract both density and sound velocity sensors can be used. RHOTEC is often preferred because of its even higher accuracy compared to SONATEC.

For density measurement, the liquid consisting of 2 components flows through a U-shaped tube. While the tube is electronically excited to oscillate at resonance, the oscillation frequency is observed. Any change in the fluid density has an impact on the detected signal and can thus be identified. Based on the correlation between concentration and density, the concentration is calculated and displayed.

E. SONATEC

Application and Measurement Principle:

Brewing is divided into milling, malting, mashing, lautering, boiling, fermenting, storage, filtering and filling. Lautering is the separation of the extracts won during mashing from the spent grain to create wort. During boiling hops are added which contribute aroma and flavor compounds to the beer. Lautering and boiling take place in the brewhouse and are controlled depending on the amount of extract. Breweries need to measure the extract concentration with precision to maintain beer quality. For the measurement of this 2-component system consisting of water and extract both density and sound velocity sensors can be used. SONATEC is often preferred because of its easy installation. SONATEC HW is designed for direct installation in the wort kettle. This instrument contains an integrated cleaning nozzle.

The speed of a sound pulse between a transmitter and a receiver is measured. The sound pulse is created by piezo-elements and moves perpendicular to the product flow. Based on the correlation between concentration and sound velocity, the concentration of the 2-component liquid is calculated and displayed.